Basic Information

|

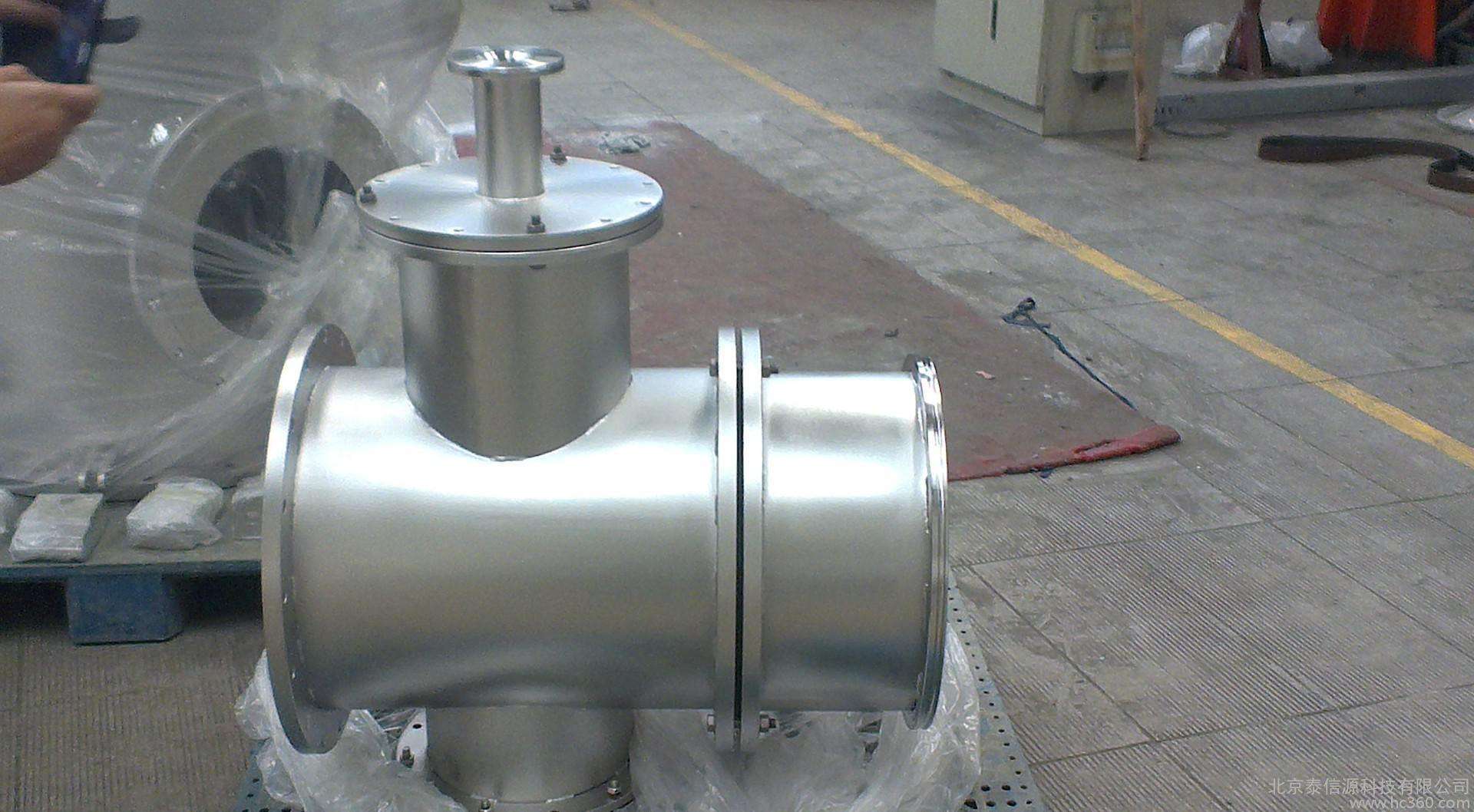

BW has 32 sets 3-axis/4-axis/5-axis CNC equipment in house. BW’s CNC machining capabilities enable us to produce the finest, highly accurate parts, full-functioning engineering prototypes, piece parts and injection molds. Fast turnaround and high accuracy on CNC parts or molds can be achieved with a wide variety of materials. BW CNC turning capabilities include live tooling which allows us to turn & mill at the same time so features like axial and radial holes, flats, grooves, and slots can be achieved. Max Milling Size : 2500*1400*650mm Tolerance : ±0.07mm CAD Format Request : IGS/STP/STEP/X-T/Catia |

Basic Information

| Machining Process | Main Material | Surface Finish |

|---|---|---|

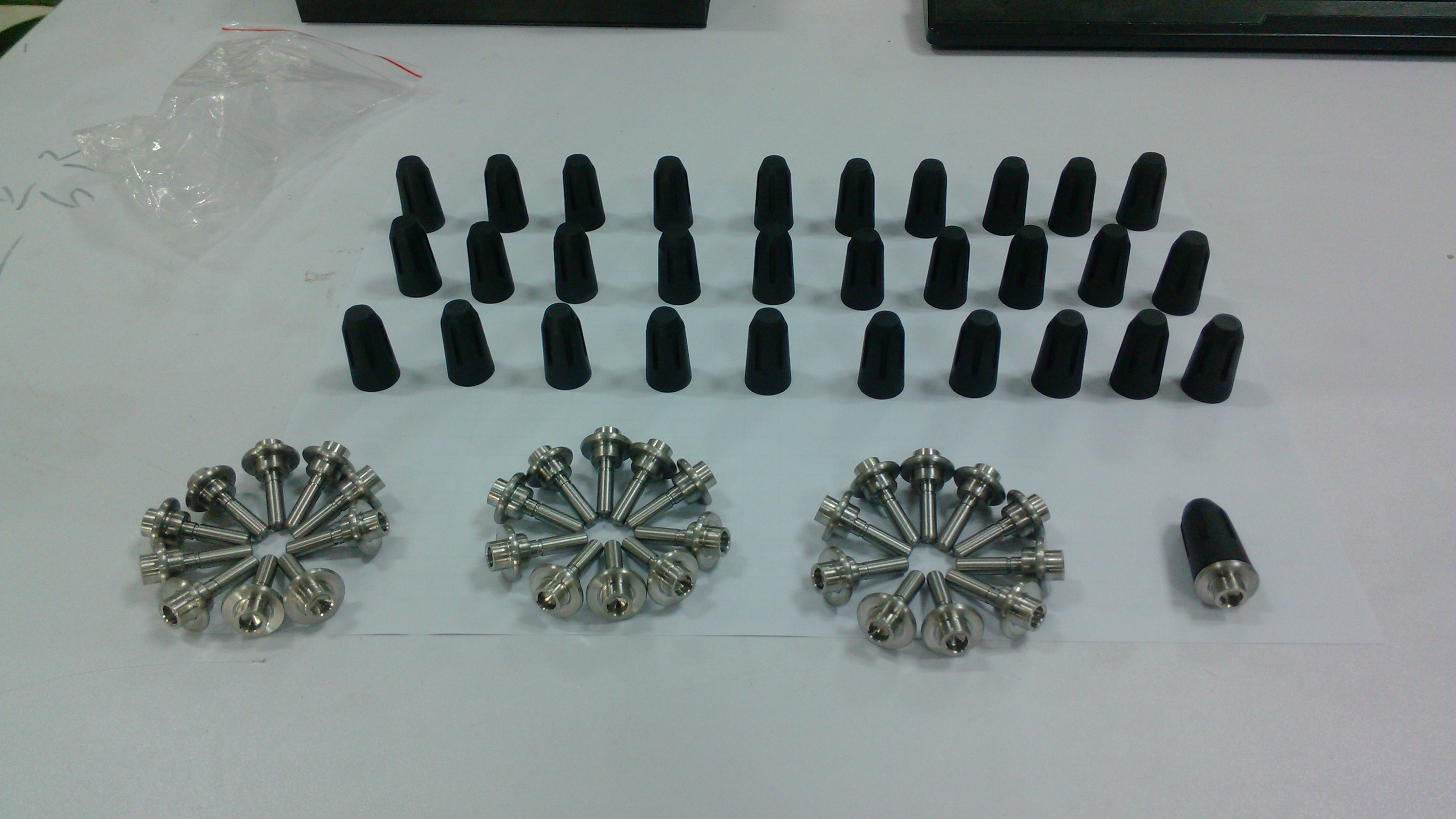

| 3-Axis /4-Axis /5-Axis High Precision CNC | Plastic(ABS, PC,PMMA, PA,PE,POM, PET,PPE, PP,etc.) | Polish /Spray Paint /Chrome Plate /Water Transfer /Laser Engrave |

| Brass /Copper | Plating Nickel /Chrome /Zinc | |

| Aluminum | Anodize /Powder Coat /Sandlast /Paint /Brush /Polish /Laser Engrave | |

| Steel(Stainless Steel /Mild Steel /Carbon Steel /Spring Steel) | Polish /Passivate /Sandblast /Nickel /Chrome /Zinc /Powder Coat /Anti-Corrosion |